- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Customer Case

- Contact Us

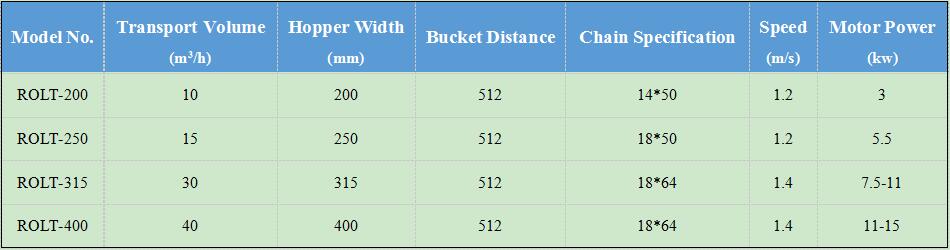

Ring chain bucket elevator:

The width of the bucket shows the performance of the elevator. Basic parameters are accordance with GB3826-85 "vertical bucket elevator type and basic parameters".

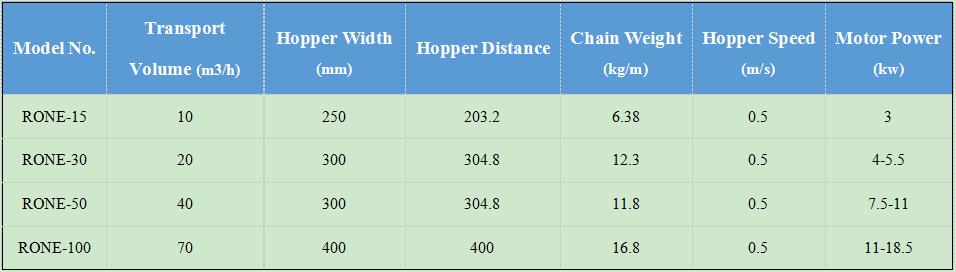

Plate chain elevator:

This plate chain elevator is the new product developed by foreign advanced technology. The series elevator is suitable for the vertical conveying of powder, granular and lump material, and also can improve the large and polish material. The material temperature is generally more than 200 degrees C, and the lifting height is 40m max. Its main features are: wide range of lifting, large transport capacity, small driving power, inflow feeding, gravity induced unloading, long service life, high lifting height, good sealing, stable and reliable operation, convenient operation and maintenance, compact structure, rigidity and low running cost.

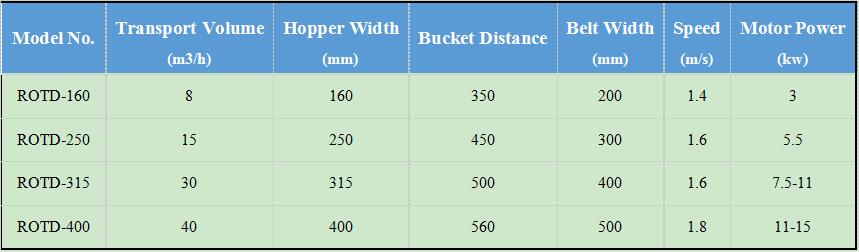

Rubber belt bucket elevator:

The width of the bucket shows the performance of the elevator. Basic parameters are accordance with GB3826-85 "vertical bucket elevator type and basic parameters".

I. Product Structure:

1. Ring chain bucket elevator:

The ring chain elevator is mainly composed of nose, tail, middle section, ring chain, hopper, detection device and so on.

2. Plate chain elevator:

The plate chain elevator is composed of running parts, driving device, upper part, middle casing and lower part.

Operation parts: composed of hopper and sleeve roller chain. NE15 and NE30 are single row chain, while NE50-NE800 are double row chain.

Driving device: a variety of drive, (according to the actual needs of users). The driving platform is equipped with repair frame and railing. The driving device is divided into two types, left and right.

Upper part: equipped with track (double row chain), backstop and discharge port with rubber sheet.

Middle section: part of the middle section is equipped with tracks (double chains) to prevent the chain from swinging during work.

Lower device: installation of automatic tensioning device.

3. Rubber belt bucket elevator:

The belt elevator is mainly composed of nose, tail, middle section, canvas belt, hopper, detection device and so on.

II. Product Performance and Characteristics:

1. Ring chain bucket elevator:

Function: to lift up granular and small non abrasive and semi abrasive materials.

The chain is high temperature resistance, high yield strength, good elastic deformation, suitable for high temperature conditions.

This product has the advantages of small size, convenient installation, simple maintenance, low failure rate and so on.

Connected to the dust removal system to enhance the overall system's dust removal effect.

Equipped with automatic detection alarm device, improving the overall automation control level of the equipment.

2. Plate chain elevator:

Kinds of structural materials:

Conveying chain plates: 45#, tempered hardness: 35 degrees; Pin shaft: 35Crm.Quenching hardness: 42 degrees;

Sleeve: 40Crm. Quenching hardness: 48 degrees; Roller: GCr15. Quenching hardness: 65 degrees; Hopper: manganese plate wear-resistant strip.

Good sealing, less environmental pollution.

Easy to operate and repair, less vulnerable parts. Extremely low use cost due to low energy consuption and maintenance.

3. Rubber belt bucket elevator:

Working temperature for belt elevator is generally limited to - 15 C to 60 C. Wide application.

This product has the advantages of small size, convenient installation, simple maintenance, low failure rate, smooth operation and so on.

Connected to the dust removal system to enhance the overall system's dust removal effect.

Equipped with automatic detection alarm device, improving the overall automation control level of the equipment.

III. Model Selection and Technical Parameters:

1. Ring chain bucket elevator:

2. Plate chain elevator:

3. Rubber belt bucket elevator:

(Note: the specific model is based on the actual design.)