- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

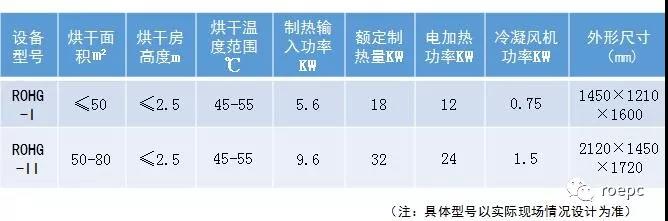

As an important part of lost foam casting, drying room is an important precondition and guarantee to produce qualified castings. Through technology upgrade and process improvement, the intelligent drying room is running well and the expected effect is achieved.

Fully automatic temperature and humidity process control, high control accuracy, flexibility and convenience. The heat exchanger does not need special technology in the heat transfer process. Closed circulation of hot air circulation mode is conducive to reducing operation energy consumption. The heat recovery through evaporator increases the efficiency of heat pump, improves the level of energy efficiency ratio (COP), and reduces energy consumption.

Advantage:

1. energy saving

Energy conservation is the starting point and the main advantage of the initial application of heat pumps.

2. qualified output

Heat pump drying is a mild drying method, which is close to natural drying. The evaporation rate of surface moisture is close to that of internal moisture moving towards the surface, which makes the dried articles have good quality, good color and high grade of products.

3. The drying parameters are easy to control and wide in range

In the process of heat pump drying, the temperature, humidity and circulating flow of circulating air can be controlled accurately and effectively, and auxiliary heating device is added.

4. Environment-friendly

Material drying requires not only improving product quality and saving energy consumption, but also being environmentally friendly. Based on the same evaluation criteria, the impact of heat pump on global warming is very small compared with the CO2 released by electricity. Friendly environment is the advantage of heat pump drying. At present, foreign countries advocate the application of heat pump to reduce CO2 emissions, which will be further applied.

Application of heat pump in lost foam drying room:

After the model is made, the EPC needs to coat the surface with a certain thickness of paint to form the inner shell of the mold. Generally, it is coated twice or three times, so that the coating thickness is 0.5-2 mm. After finishing the coating on the surface of the EPC, the coating needs to be cured and fully dried in a certain period of time by drying for subsequent production. The coating should be dried at 40~50 C, the drying temperature should not be too high, otherwise the surface will be prone to cracks. Each coating must be dried before the next round of brushing or modeling, if the coating is not dry, molten steel will encounter a large amount of water when pouring gas, resulting in spraying back, and the coating is not dry, poor permeability of the coating, gas can not be discharged in time, easy to make the casting gas hole, slag hole.

1. Heat pump evaporative pattern drying room can effectively reduce the environmental humidity, the drying room humidity is controlled at about 20%, with the room temperature at about 50 degrees, the interaction of the two makes evaporative pattern drying rate increased by 25%; drying single brushing time is only 8-12 hours.

2. The hot air velocity is faster, the turbulence in the room is increased, and the drying of EPC is uniform, which effectively prevents the cracking of coating.

Compared with the traditional drying method of EPC with heat source, the EPC dryer based on heat pump technology has the following technical characteristics:

1. Automatic control. Touch screen control, microcomputer operation, saving manpower cost, convenient and easy to master.

2. Save space. It occupies less space than traditional drying houses and reduces investment. The equipment is easy to install and convenient to debug.

3. Energy saving and environmental protection. The energy efficiency ratio can reach more than 3.0, the unit energy consumption can do more than three times the work, the system will automatically stop after meeting the set temperature requirements, will not continue to operate.

4. Efficient dehumidification: According to the dew point temperature at different temperatures and humidities, control the air flow rate on the surface of the evaporator and the flow rate of refrigerant in the evaporator to increase the dehumidification efficiency and meet the drying requirements.

5. Efficient and Energy-saving: Closed-loop heating reduces the energy loss caused by dehumidification, recovers the huge latent heat of moisture in wet materials, improves the temperature rising speed in the drying room, shortens the running time of the unit, and greatly improves the comprehensive energy efficiency of the unit.

6. Environmental protection is safe and pollution-free: drying medium circulate in closed system, environment friendly.