- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

EPS silo as known as EPS aging silo. This device is used in LFC production line. Pre foamed EPS beads are placed in a dry and ventilated storage silo for a certain period of time, making inside and outside of beads pressure balanced, optimizing the elasticity and the expandability, and removing water on the bead surface.

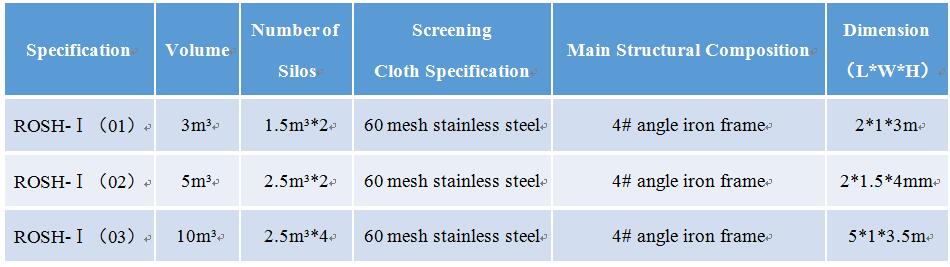

These silos are available in a range of sizes and configurations to meet diverse production requirements. Customization options are also available to tailor the size of the EPS silo to the specific demands of the customer.

EPS aging silos are a vital part of the manufacturing process for expanded polystyrene (EPS). These specially designed storage facilities are used to store the raw EPS beads, which are the primary material for creating EPS foam products. The silos are equipped with features that protect the EPS beads from moisture, dust, and other environmental factors that could degrade the material. This is crucial, as even a small amount of moisture can ruin the properties of EPS beads, rendering them unusable. The silos also maintain optimal temperature and humidity levels to ensure the EPS beads remain in good condition, preventing production downtime and material waste.

One of the key advantages of EPS aging silos is their advanced material handling system. This system minimizes the risk of contamination and damage during the loading and unloading of EPS beads, while also improving efficiency and ergonomics for workers. Additionally, the silos have a well-organized storage system with multiple racks, allowing for systematic arrangement of EPS beads based on size, grade, or color. This facilitates efficient inventory management, waste reduction, and easy access to materials.

EPS aging silos are essential for maintaining high standards of quality and efficiency in the production of expanded polystyrene. Their unique features, including advanced material handling systems, temperature control, and organized storage, make them an ideal choice for manufacturing plants.

1. The overall structure has a scientific permeability, which is conducive to the curing of polymer materials (EPS, STMMA or EPMMA).

2. Foam beads can be efficiently input and output.

3. LIght structure, bolt connection, convenient to disassemble and install.

1. Main frame

2. Outer screen

3. Cone bucket

4. The outlet ( shape optional)

EPS foam is widely used in retail and consumer goods packaging, such as protective packaging for electronic products, furniture, and household goods. EPS recycling machines can recycle EPS foam packaging waste generated by retailers and consumers, supporting sustainable packaging initiatives and reducing landfill waste.

The EPS silo is commonly utilized in industries that require a substantial quantity of expanded polystyrene material, including the production of EPS blocks, insulation materials, and packaging products.

Auto Silo EPS Bead Storage is an automated system for storing expanded polystyrene (EPS) beads, ensuring efficient organization and retrieval in a controlled environment.

Automation: The Auto Silo EPS Bead Storage system uses an automated system for loading, unloading, and organizing EPS beads, reducing manual labor and improving efficiency. Touchscreen and PLC

Level sensors (upper position sensor, lower position sensor).

Controlled Environment: It provides a controlled environment to maintain optimal conditions for storing EPS beads, preventing degradation and preserving quality.

Space Optimization: The system optimizes space utilization by vertically stacking EPS beads, maximizing storage capacity within a limited footprint.

Inventory Management: Fire-resistant EPS silo storage bags. It enables precise tracking and management of inventory, allowing real-time monitoring of bead levels and efficient retrieval when needed.

Customizable Configuration: Auto Silo EPS Bead Storage offers customizable configurations to accommodate different storage capacities and operational requirements, providing flexibility for various applications.

Ruiou is a leader in quality, having passed ANAB, ISO9001, ISO14001, and GB/T28001 certifications, setting the standard for excellence in the industry.

Ruiou is a leader in quality, having passed ANAB, ISO9001, ISO14001, and GB/T28001 certifications. As a professional provider, Ruiou offers a full range of lost foam solutions, including equipment, molds, high-end castings, coatings, special sand, and comprehensive project design, R&D, and technology training. Contact us today for precision and excellence!