The foam pattern is the core element in the lost foam casting process. It acts as the mold for the final casting and plays a vital role in determining the quality of the finished product.

Key Steps in Pattern Production:

Pattern Design: Engineers use CAD (Computer-Aided Design) software to create highly accurate foam patterns based on the specifications and geometry of the desired part. This ensures a precise match between the pattern and the final casting.

Pattern Molding: Foam blocks are shaped into the exact specifications using methods like CNC machining, 3D printing, or manual sculpting. These patterns must be free of imperfections to ensure smooth casting.

Coating Application: To enhance the foam pattern’s durability and heat resistance, a refractory coating is applied. This protective layer helps withstand the intense heat during metal pouring and prevents deformation of the foam pattern.

2. Pattern Assembly

After the foam patterns are produced, they undergo assembly to prepare them for the casting process.

Key Steps in Pattern Assembly:

Gating and Venting: Channels are incorporated into the foam patterns for molten metal flow (gates) and air escape (vents). These channels ensure proper filling and prevent defects in the casting, ensuring a smooth and uniform metal flow.

Cluster Formation: The individual foam patterns are assembled into clusters and attached to a sprue system, creating a “pattern tree.” This configuration makes it easier to pour molten metal into multiple parts at once and ensures uniform metal distribution.

3. Mold Preparation

Preparing the mold is a critical part of the lost foam casting process. It involves the following steps:

Key Steps in Mold Preparation:

Flask Setup: The foam pattern clusters are placed inside a flask, a container that holds the sand. The flask supports the sand during the casting process and ensures the mold maintains its shape during metal pouring.

Sand Compaction: Unbonded sand is packed tightly around the foam pattern clusters. The compaction ensures that the sand is uniform and stable, which helps maintain the mold’s integrity during pouring and cooling.

4. Casting

The casting stage is where the magic happens—molten metal is poured into the prepared mold to create the final part.

Key Steps in Casting:

Preheating: To avoid thermal shock, the mold is preheated before metal pouring. This step ensures that the molten metal flows properly and evenly throughout the mold.

Metal Pouring: The molten metal is poured into the cavity created by the foam pattern. As the metal fills the mold, the foam patterns vaporize, leaving behind a void that is now filled by the molten metal.

Cooling and Solidification: After pouring, the metal begins to solidify within the mold cavity. The cooling process is carefully controlled to avoid defects such as cracking or warping, ensuring the cast part has optimal mechanical properties.

5. Finishing

Once the casting has cooled, it undergoes finishing operations to remove excess material and achieve the desired surface quality.

Key Steps in Finishing:

Shakeout: The casting is removed from the mold, and any remaining sand is shaken off.

Cleaning: The casting is thoroughly cleaned to remove residual sand, coatings, and surface imperfections.

Machining: If necessary, the casting undergoes machining operations to meet tight tolerances and finalize the dimensions of the part.

Conclusion

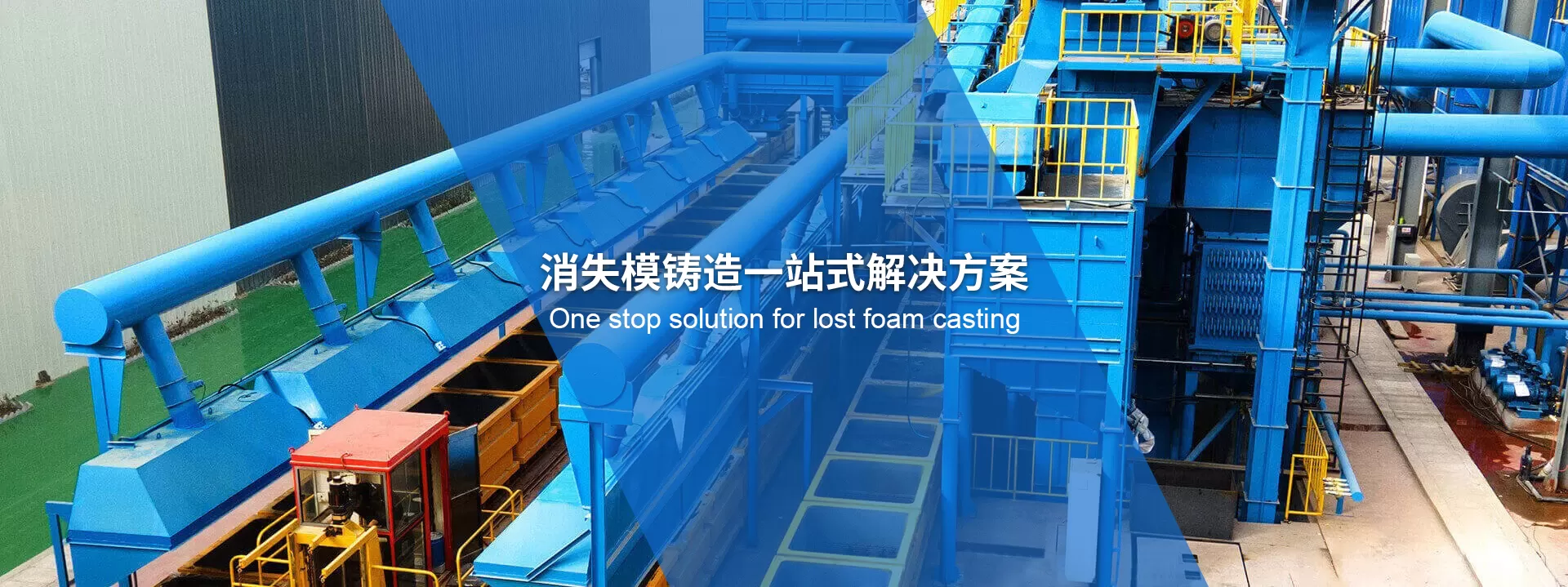

Lost foam casting is an innovative and efficient method for producing complex metal parts. By eliminating the need for core making and traditional mold repairs, LFC offers cost-effective and high-quality castings. From pattern production to finishing, each step plays a crucial role in delivering precision and accuracy.

At RUIOU, we specialize in lost foam casting and provide expert guidance to ensure that your casting needs are met with the highest standards of quality. Whether you’re in the automotive, aerospace, or industrial sector, we have the expertise and technology to help you achieve exceptional casting results. For further inquiries about lost foam casting or to explore our range of casting solutions, don't hesitate to contact us. As your trusted supplier, we're committed to providing expert guidance and top-quality products to meet your casting needs.