- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

The sand box used in LFC is made of steel plate and channel steel with reasonable structure. The internal gas chamber is distributed in bottom of the box and four corners of the box. It can make the most reasonable negative pressure field when the casting is vacuumed in the sand box, so that the full box castings can be formed well and avoid the defects.

Product Structure:

The sand box is mainly composed of body, channel steel flange, lifting lug, negative pressure port, top shaft, walking wheel and so on. The sand boxes with wheels are suitable for automatic production line, boxes without wheels are suitable for unpowered idler production line or semi-automatic production line.

Product Performance and Characteristics:

1. The internal gas chambers of the box are divided into 3 groups, which are located at the bottom of the box, around the box and the four corners of the box. The distribution is reasonable, so as to ensure the reasonable negative pressure field inside the box when pouring, making the casting good and avoiding the defects, and the internal airway structure also plays a role in strengthening the box. There is no air chambers in the four corners of the bending sand box, but the air chamber on the box is wider than the ordinary sand box.

2. All boards of box are welded double sides. The welding seam is tight to ensure the tightness of the air chambers.

3. Sand box material is solid, good strength to ensure long-term use, not easy to deformation.

4. When no turnover, bottom leakage sand device can be used. The whole production line reduces the use of the turnover machine and reduces the cost.

5. If dimension of the sand box is too large, it can use the sectional design to ensure the strength of the sand box and facilitate the hoisting of customers. Also, too large sand box be designed to discharge from bottom or side.

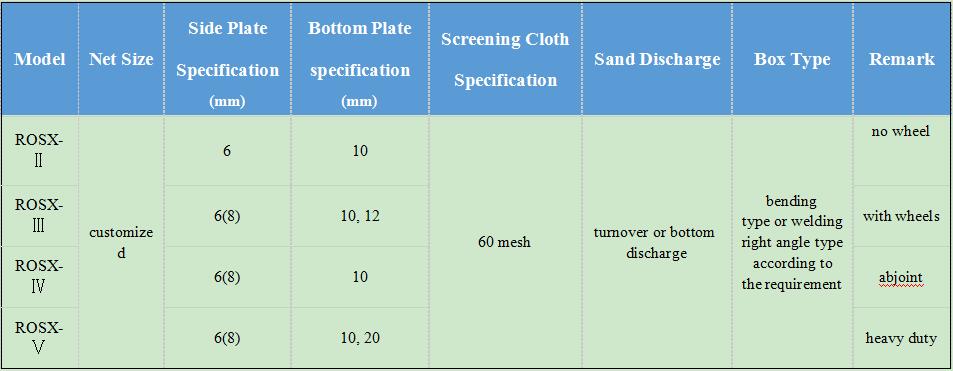

Model Selection and Technical Parameters:

(Note: the specific model is based on the actual design.)