- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

This Lost Foam Casting Sand Conveyor is mainly used for sand conveying in LFC sand treatment system. Working temperature is generally limited from -10℃ to 100℃. It can be used for horizontal or tilted transport.

The Lost Foam Casting Sand Conveyor is an essential piece of equipment in the LFC sand treatment system, specially designed for the efficient and safe transportation of molding sand. Operating within a wide temperature range of -10°C to 100°C, this industrial sand conveyor is perfect for use in Lost Foam Casting (LFC) applications. It provides reliable, stable operation to move sand across horizontal or tilted conveyors, improving your foundry sand handling process.

Our LFC sand transport belt conveyors are engineered to prevent sand spillage, ensuring your casting sand moves safely and securely throughout the system. Designed for durability and ease of maintenance, this conveyor system is built to last and handle high-capacity sand transport needs.

Capacity: Designed to handle large volumes of molding sand at up to 30 tons per hour, this conveyor meets the high demands of industrial sand transport.

Temperature Range: Efficient operation in temperatures from -10°C to 100°C, suitable for various foundry environments.

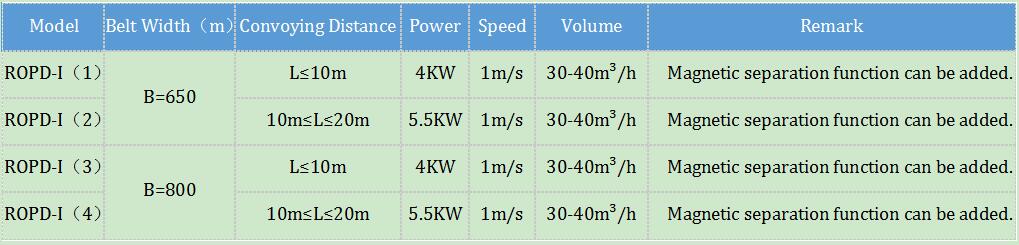

Belt Width: Standard belt widths of 650mm or 800mm, with custom belt options available based on your sand transport needs.

Material Compatibility: Can transport molding sand, casting sand, and other similar granular materials without spillage or contamination.

(Note: the specific model is based on the actual design.)

The Lost Foam Casting Sand Conveyor consists of the following main components:

Motor Reducer: Ensures smooth and efficient power transmission for stable operation.

Rollers & Idlers: Provide support and reduce wear, ensuring that the conveyor operates smoothly over time.

Belt: Durable and designed to withstand heavy industrial sand transport demands.

Brackets: Strong and sturdy, designed to support the conveyor frame.

Stable Operation for Sand Transportation

The three-roller design ensures that no molding sand or casting sand spills during the transport process. This stability is essential for maintaining the cleanliness of your workshop and preventing material loss.

Temperature Resistance

The high-temperature sand belt conveyor operates efficiently in temperatures from -10°C to 100°C, making it suitable for various foundry applications. Whether you're handling molding sand for Lost Foam Casting or other materials, this conveyor is built to endure harsh conditions.

Versatile Conveying Options

Whether you need horizontal or tilted sand transport, this conveyor offers the flexibility to suit your production line's layout, optimizing space and enhancing system efficiency.

Low Maintenance & Long Service Life

The simple structure of this conveyor makes it easy to maintain, minimizing downtime and repair costs. It is manufactured according to national standards, ensuring a long service life with minimal upkeep.

Reliable and Customizable

Designed for high-capacity sand handling, this system is ideal for LFC sand treatment processes. It is also available for customization based on your specific requirements, ensuring a perfect fit for your foundry or industrial facility.

Lost Foam Casting Systems: Perfect for sand transport in LFC applications, ensuring smooth handling of molding sand and casting sand.

Industrial Sand Conveying: Suitable for use in foundries, casting plants, and other industrial environments where molding sand needs to be efficiently moved.

High-Temperature Applications: Ideal for sand transport in environments with temperatures ranging from -10°C to 100°C, perfect for foundry operations.

OEM Solutions for Custom Needs: We offer OEM sand conveyors tailored to your exact specifications, ensuring that our products fit perfectly into your sand treatment system.

High-Performance Conveying: Designed for efficient sand transport in LFC sand treatment systems, ensuring smooth and safe handling of molding sand.

OEM Customization: As a leading supplier of sand conveyors, we offer custom belt conveyors designed to meet the unique needs of your foundry. Whether you require specific dimensions or special features, we can deliver a tailored solution.

Durable and Long-Lasting: Built to withstand the harsh conditions of industrial environments, our Lost Foam Casting Sand Conveyors offer long-term reliability and minimal maintenance requirements.

Cost-Effective Solution: Reduce downtime and operating costs with our high-capacity and easy-to-maintain conveyor systems. We provide the most cost-effective sand transport solutions for industrial applications.

Looking for a reliable sand belt conveyor for your Lost Foam Casting system? Contact us today for a customized quote. Our OEM sand conveyors are designed to meet the specific requirements of your foundry, offering efficient, high-capacity sand transport solutions at competitive prices.

We also offer fast delivery and exceptional customer support. Let us help you optimize your sand handling process.