- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

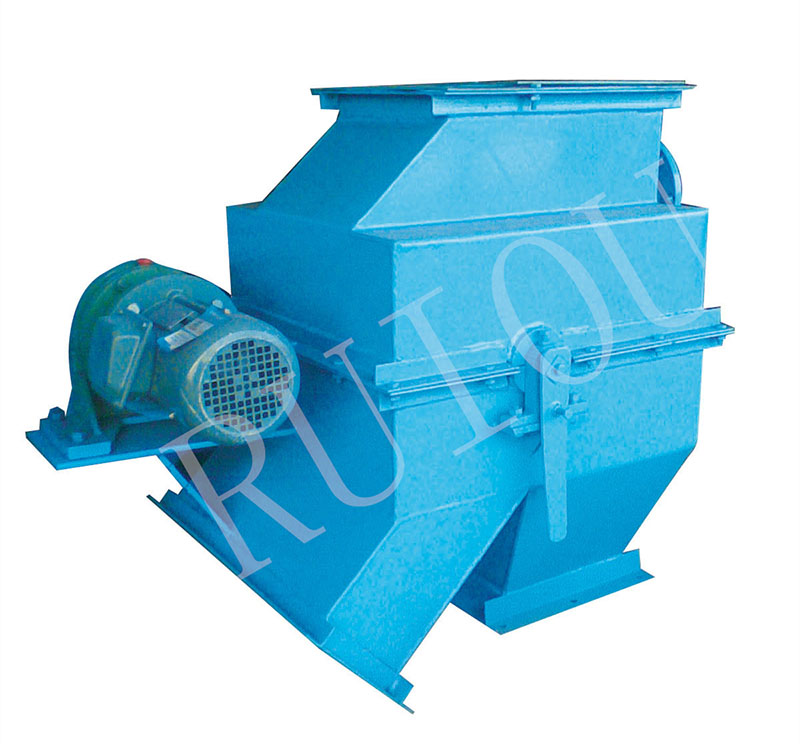

Lost foam casting is a green casting process with nearly no allowance and precise molding. Magnetic separator is a sand treatment production line in lost foam casting to realize automatically casting falling sand, impurity screening, iron bean magnetic separation conveying and old sand conveying& cooling. After the molding sand enters the equipment through the sand inlet, the doped iron impurities are adsorbed on the semi magnetic cylinder. Through the rotation of the semi magnetic cylinder, the impurities are brought into the non-magnetic area and slide out of the slag outlet by their own weight, thus playing a role in magnetic separation.

Separation of Magnetic Impurities: During the casting process, metallic melts may contain magnetic impurities such as iron and iron powder. Magnetic separators use a strong magnetic field to attract and separate these magnetic impurities, preventing them from entering the castings, thus improving casting quality.

Improving Casting Precision and Surface Quality: Removing magnetic impurities can prevent defects from forming on the surface or inside of the castings, thereby improving casting precision and surface quality, and reducing subsequent finishing and processing.

Improved Casting Precision and Surface Quality: Fewer defects in castings lead to less need for extensive post-processing, thereby reducing costs.

Lower Production Costs: Streamlined casting processes reduce labor and equipment investment, shortening production cycles.

Enhanced Design Flexibility: The ability to produce more complex and precise castings expands product design possibilities.

Environmental Protection: Reduction of environmental pollution aligns with sustainable development principles.